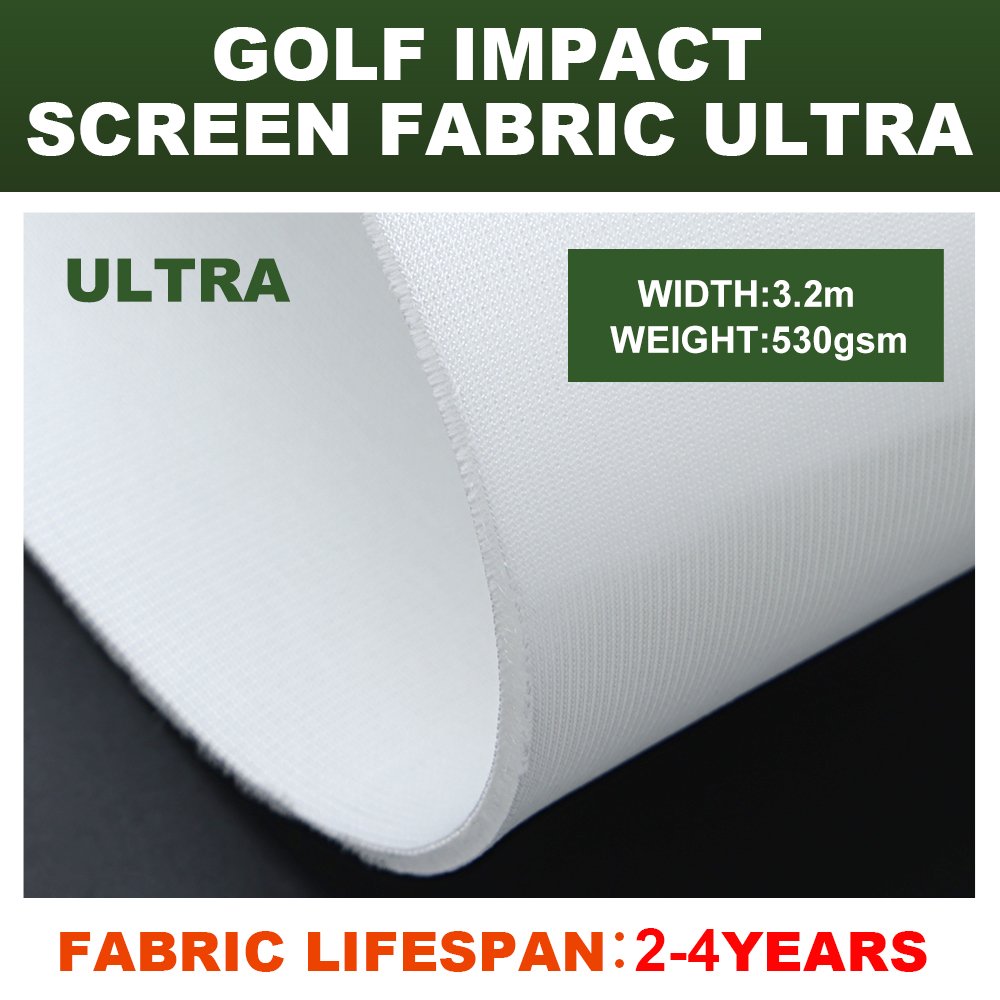

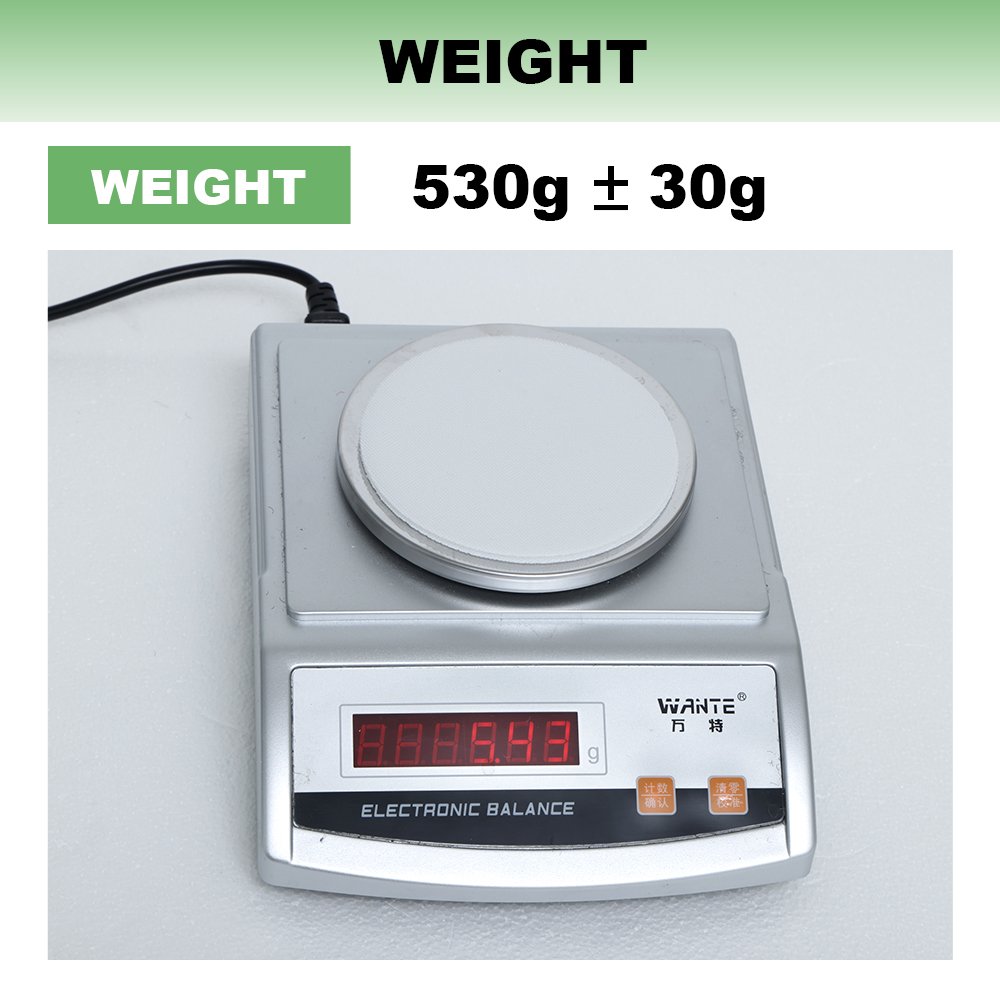

Golf Simulator Screen Material-B Type 540gsm Ultra

Please select your preferred fabric, size, and edge finishing. Our system will automatically calculate the estimated price. Once you submit your inquiry, our team will get back to you within 24 hours with a detailed quote and customized solution.

golf simulator screen material (Ultra 540gsm) is built for 6–12 months of frequent use. The dense warp-knit cuts shot noise, and the low-rebound design limits bounce-back for safer, quieter bays. Ideal for home setups, commercial simulators, and pro-level use.

Other fabric weights available.

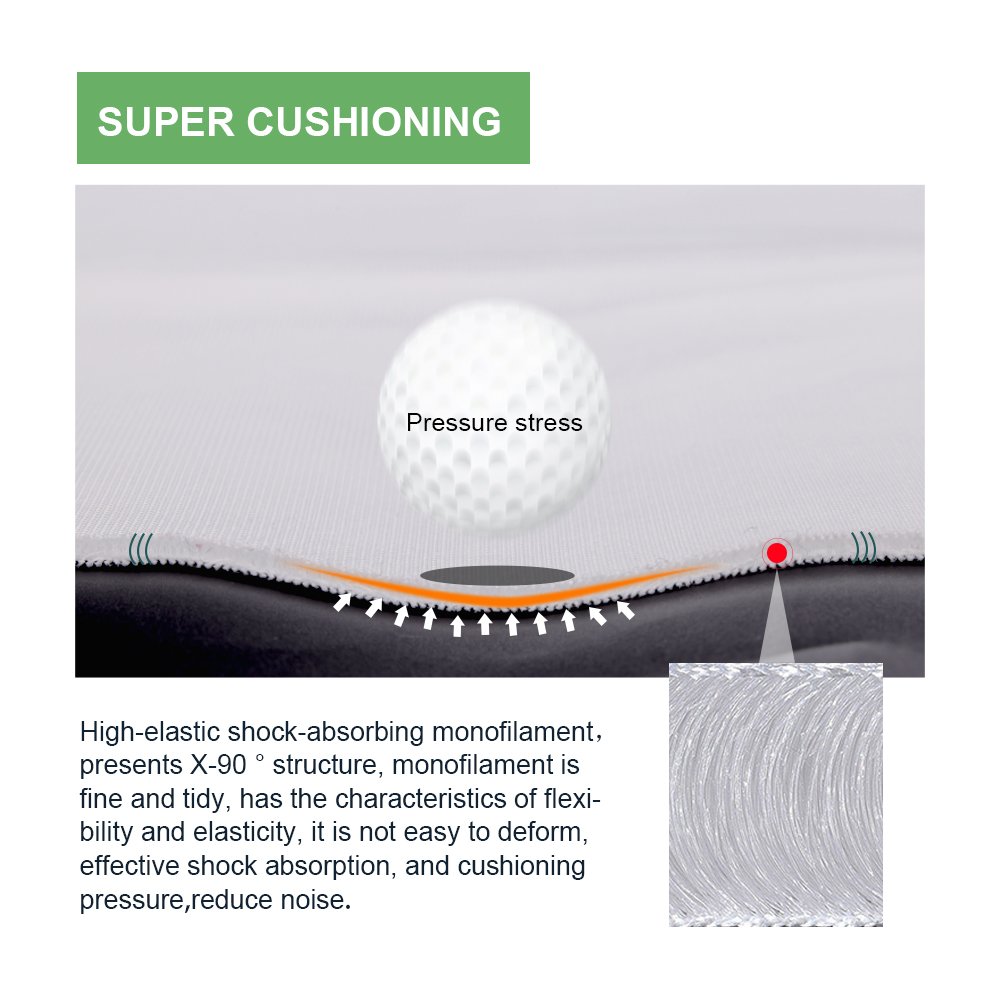

Super Cushioning Technology – The Ultimate Impact Solution

Experience unmatched performance with our X-90° High-Elastic Monofilament Structure, engineered to deliver professional-grade cushioning and noise reduction.

Why Our Cushioning Stands Out:

✔ X-90° Precision Weave – Advanced filament alignment for optimal shock absorption

✔ Elastic Yet Stable – Flexible enough to cushion, strong enough to resist deformation

✔ Noise-Reduction – Lab-tested to reduce impact sound by up to 67%

✔ Pressure Dispersion – Protects both balls and equipment from stress damage

Where cutting-edge material science meets golf simulator perfection.

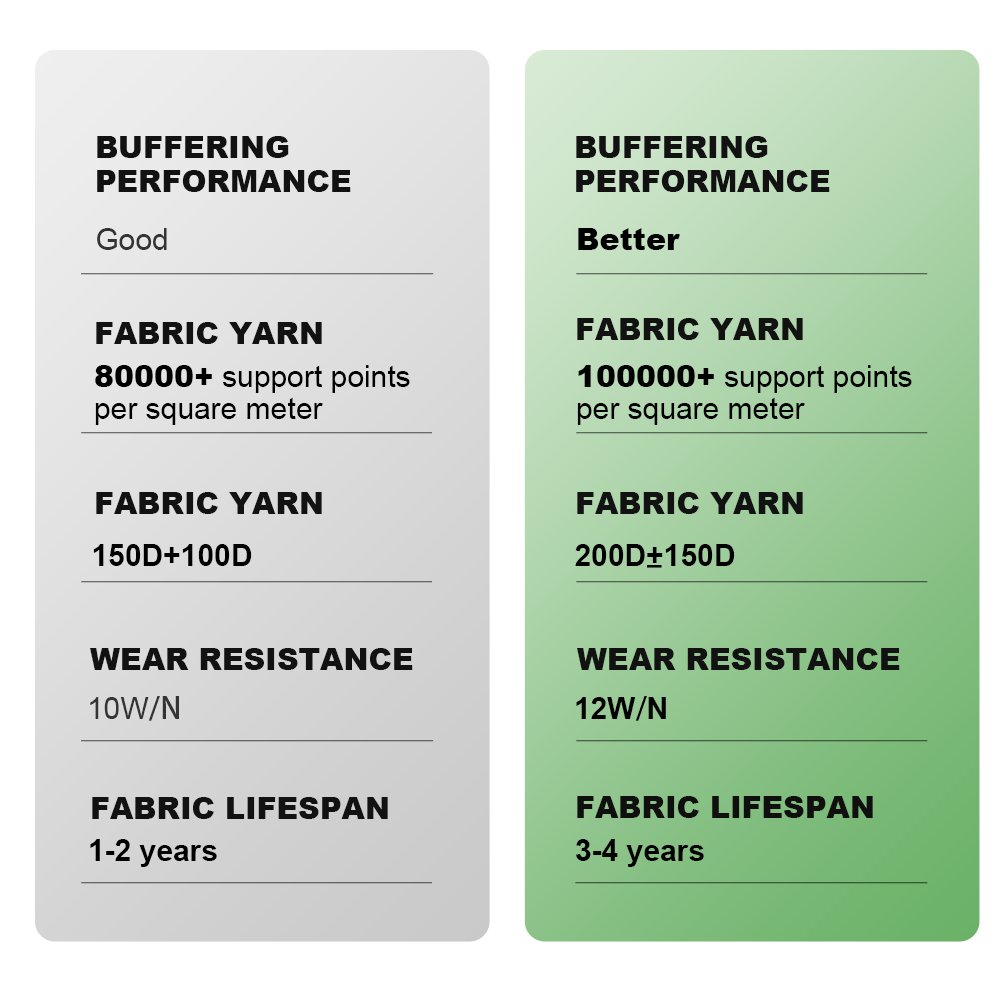

High-Density Fabric Engineering – Precision Meets Performance

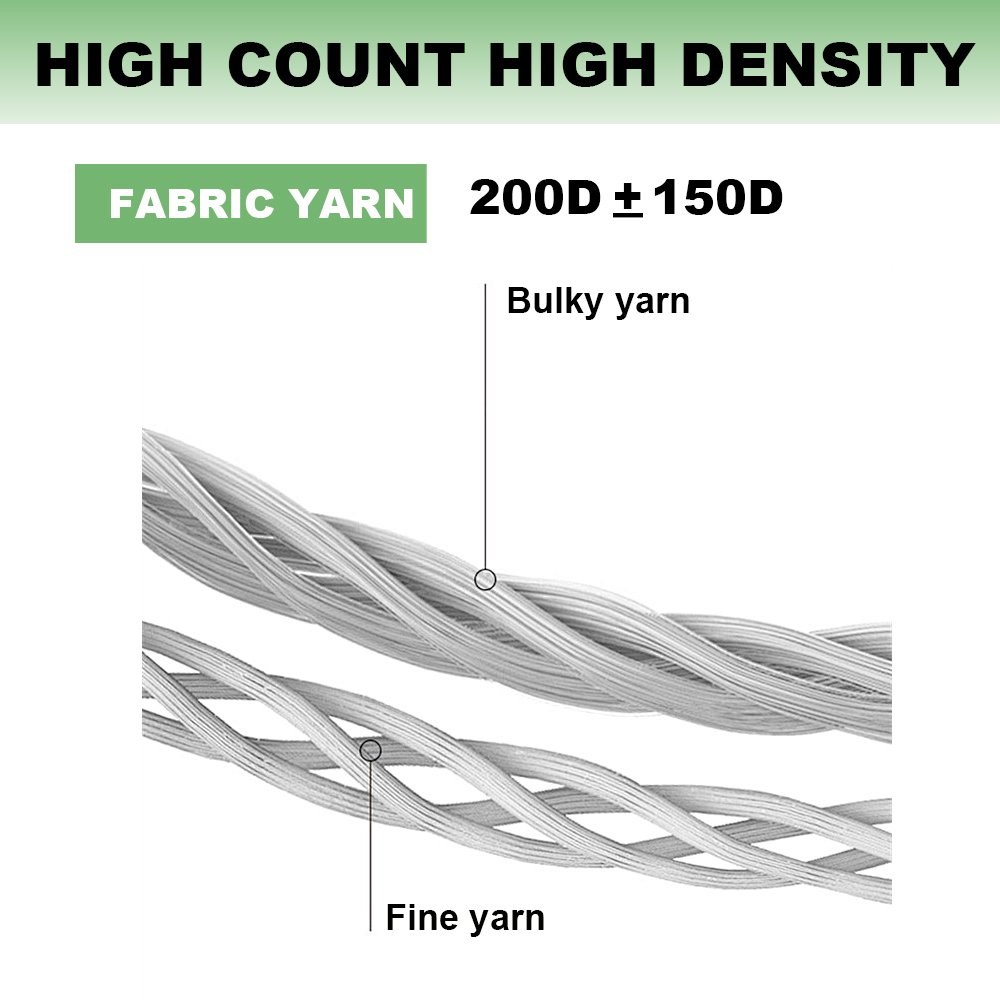

Our 200D+150D hybrid yarn construction redefines golf impact screen durability:

Dual-Yarn Advantage

✔ 200D Bulky Yarn Base – Unmatched tear resistance and structural integrity

✔ 150D Fine Yarn Surface – Ultra-smooth projection quality with zero texture interference

✔ Military-Grade Density – 42% tighter weave than industry standard (328 threads/sq.in)

✔ Dynamic Stress Distribution – Intelligent load transfer across the entire surface

Where every thread is calculated for your perfect swing.

Military-Grade Wear Resistance – Built to Endure

Engineered for relentless performance, our screens deliver 12W/N abrasion resistance – the industry’s toughest standard for golf impact screens.

Endurance You Can Trust:

✔ 12W/N Certified Durability – Withstands 50,000+ simulated swings (ASTM D3886 tested)

✔ 2-4 Year Lifespan Guarantee – Outlasts competitors by 2X in commercial environments

✔ Self-Heating Fiber Tech – Special coating reduces friction-induced wear

✔ UV & Moisture Resistant – Perfect for indoor/outdoor simulator setups

Play harder. Last longer. Replace less.

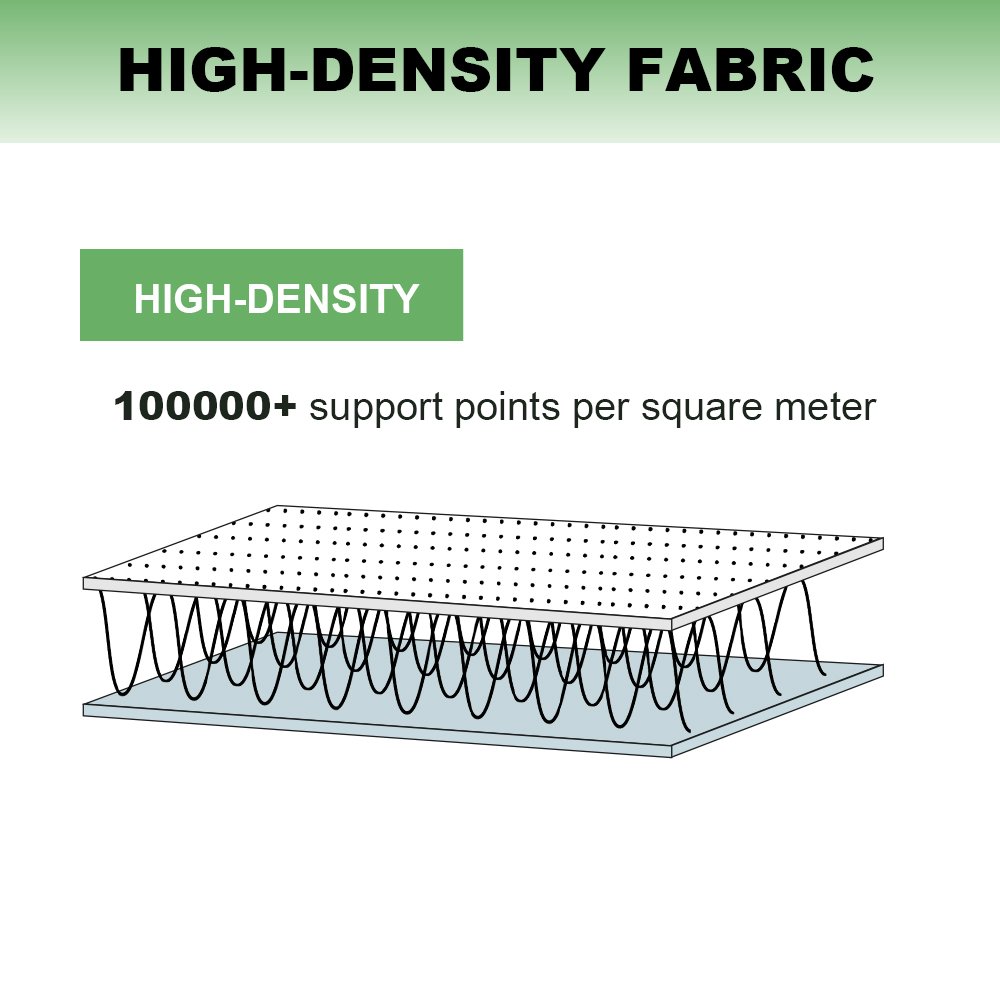

Ultra-Density Fabric Technology – The Foundation of True Performance

With 100,000+ support points per square meter, our high-density fabric sets the new standard for golf impact screens:

Density That Delivers Results:

✔ Micro-Support Matrix – Evenly distributes impact force across entire surface

✔ Pixel-Perfect Projection – Eliminates “hot spots” for flawless image clarity

✔ Unmatched Durability – 3X more contact points than standard screens

✔ True Ball Response – Maintains consistent rebound characteristics over time

Precision-engineered down to the square millimeter.

Related products

FAQ

We offer different weights and constructions to match usage intensity. For example, Plus ~490 gsm suits home or medium-frequency training, while Ultra ~540 gsm targets higher-frequency, heavy-duty use. In your inquiry, please specify the application scenario, estimated weekly training hours, and projection requirements so we can recommend the best option.

We support full customization: material series, finished size and aspect ratio (e.g., 16:9 / 4:3 / 1:1), edge finishing (binding, grommets, hook-and-loop), mounting accessories, and branding/packaging. For engineering projects, we can propose seamless or concealed-seam solutions. For a quote, share width × height, aspect ratio, and preferred edge finish.

Yes. We offer FR (flame-retardant) screens and can align with the relevant standard(s) required in your destination market (e.g., NFPA / EN / KS). Note your target market and regulatory requirements in the inquiry, and we’ll advise on material selection and the testing/Documentation pathway.

Samples are available (swatch book, cut piece, or small finished sample). MOQ and lead time depend on size, process, and current capacity. Once we receive full specifications, we’ll propose a sampling plan and mass-production schedule. To speed things up, please include: finished size (W × H), aspect ratio, FR requirement (yes/no), edge finish, and destination country/region.

We support FOB / CIF / DDP and quote primarily in USD. Common payment method is T/T (subject to contract). Our formal quotation will clarify tax inclusion, shipping mode, and delivery terms to facilitate internal review and apples-to-apples comparison.

We implement quality control throughout all processes (yarn → fabric → finished product). Batch inspection records and samples are available. We welcome third-party or on-site video inspections and adhere to the contractually defined AQL schedule. If any non-human quality issues are discovered upon receipt, we offer repair/replacement/repair solutions and assist with claims related to shipping damage.