I’m an internationally recognized technical blogger specializing in high-performance golf simulation projection equipment. I create technical content across independent websites and social media platforms. My goal is to provide precise insights into emerging textile technologies—like 3D mesh fabric—that are redefining virtual sports infrastructure.

Introduction: Why 3D Mesh Fabric Matters

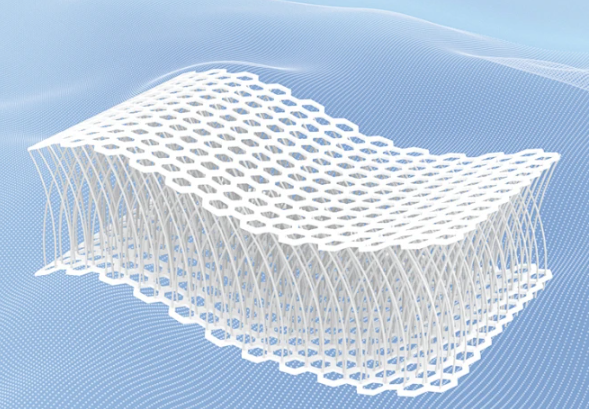

Three-dimensional spacer fabric is rapidly becoming the go-to solution in industries requiring high-performance materials. Especially in golf simulation projection screens, this fabric offers breathability, flexibility, durability, and superior projection clarity.

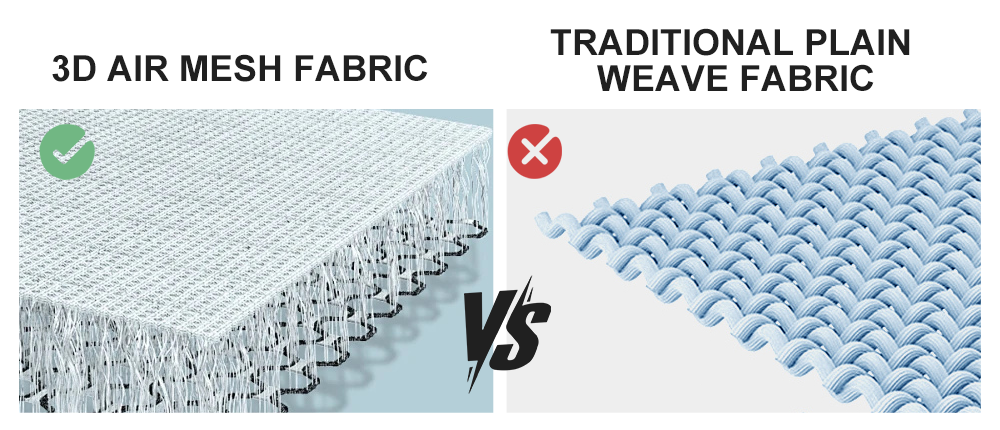

Unlike traditional woven fabrics, 3D mesh structures provide better airflow and mechanical cushioning due to their layered design. This article will dive into the construction, performance, and commercial significance of 3D mesh fabric.

The Science Behind 3D Mesh Fabric

knitted spacer fabrics are created through warp-knitting machines. These machines interlace yarns into a sandwich-like structure consisting of:

Two outer fabric layers

Spacer yarns (vertical fibers) in between

This three-dimensional construction results in:

Superior breathability thanks to open-cell structures

Improved impact absorption due to internal air gaps

Excellent mechanical stability through balanced stress distribution

Using CAD design tools, manufacturers can fine-tune the mesh density, spacer height, and fabric tension to achieve specific performance goals.

Unique Advantages of Spacer-Knitted Materials

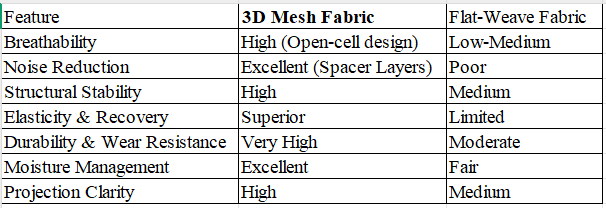

Empirical testing data shows 3D mesh fabric demonstrating approximately 35% better noise absorption and at least 20% greater durability under sustained impact compared to traditional flat-weave fabrics.

Manufacturing Challenges and Barriers to Entry

Producing 3D mesh fabric involves significant technical challenges:

- Equipment Complexity:

Warp-knitting machinery required for 3D mesh structures is technologically sophisticated, necessitating high capital investment and skilled operators. - Material Precision:

High-quality yarns must be carefully selected and precisely tensioned to maintain structural integrity and uniformity, demanding stringent quality control systems. - Technical Expertise:

Design and production of 3D structures require advanced textile engineering know-how, including the ability to manage intricate parameters like mesh density, yarn tension, and spacer control.

Due to these barriers, only manufacturers with substantial investments in technology, training, and quality assurance can consistently deliver premium-quality 3D mesh fabrics.

Strategic Significance for Wholesale Suppliers

For wholesalers and OEM fabric suppliers, adopting 3D mesh fabric technology presents substantial strategic benefits:

Market Differentiation:

The adoption of cutting-edge fabric technologies enables wholesalers to clearly differentiate from competitors still reliant on traditional flat-weave fabrics, positioning them as innovation leaders.

Enhanced Product Offerings:

The unique performance advantages offered by 3D mesh fabrics (e.g., superior breathability, noise absorption, durability) directly address the advanced needs of specialized markets such as golf simulator screens, virtual reality setups, and premium indoor sports environments.

Increased Margins:

Due to the specialized nature of 3D mesh fabrics and limited competition resulting from high entry barriers, wholesalers can achieve better pricing power and profitability.

Expanded Market Opportunities:

The versatility of 3D mesh fabrics opens opportunities in related sectors, such as automotive seating, healthcare applications (pressure-relief mattresses), and outdoor furniture, significantly broadening market scope.

Common Q&A

Q1: Why is breathability important in golf simulator screens?

A: Breathability enhances airflow, reduces heat buildup, and prevents fabric deformation, ensuring sustained performance and clarity.

Q2: How durable is Spacer fabrics compared to traditional materials?

A: Typically, 3D mesh fabric shows about 20% better durability and resistance to prolonged use and repetitive impacts.

Q3: Can 3D mesh fabric handle high-resolution projections clearly?

A: Yes, the uniform structure and stable tension of 3D mesh fabric minimize distortion, ensuring optimal projection clarity.

Q4: Is the production of 3D mesh fabrics eco-friendly?

A: Generally yes, the knitting process reduces waste compared to woven methods, making it a more sustainable production method.

Q5: Is customization possible with 3D mesh fabrics for OEM orders?

A: Absolutely, CAD-driven warp-knitting technology allows extensive customization in density, thickness, color, and specific mechanical properties.

Contact us today to request your exclusive technical white paper on advanced 3D mesh fabric solutions.